A custom-made abutment is an essential element in the area of dental implantology, acting as a tailored link that connects a dental implant to an artificial tooth, such as a crown, bridge, or denture. Customized abutments are specifically developed and customised to the patient's distinct oral anatomy as opposed to prefabricated abutments, assuring a precise fit and excellent functionality.

A custom-made abutment's major role is to produce a smooth and secure connection between the implant fixture and the replacement tooth crown, which is critical for aesthetics and performance. Customized abutments enhance the implant's longevity by adapting the particular shapes and orientation of the implant site.

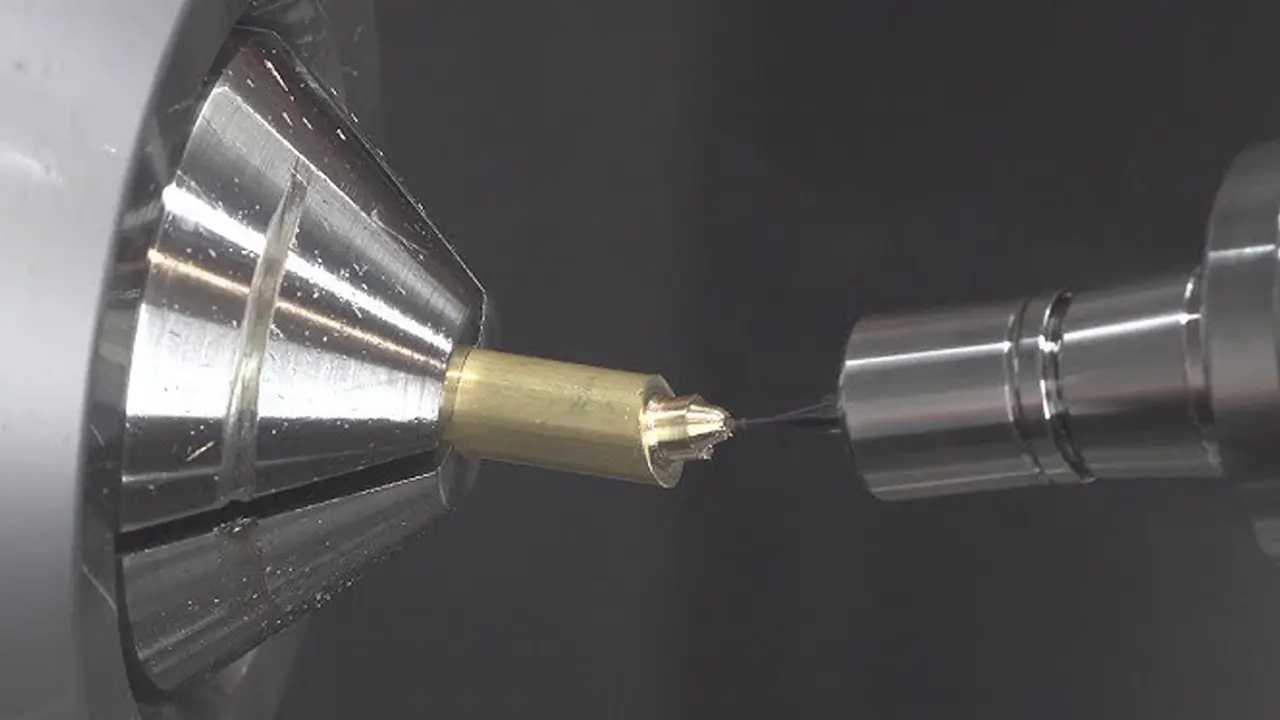

Getting a custom-made abutment entails a procedure that acquires accurate digital images or actual moulds of the patient's mouth. The imprints are used to create and assemble an individualised abutment, which is accomplished using computer-aided design and manufacturing (CAD/CAM) processes. The personalised abutment is securely bonded to the implant fixture during the last phases of the dental implant procedure.

The average cost of a custom-made abutment varies greatly based on factors such as the intricacy of the case, the components utilized, and the dental practice's physical location. Clients must budget between a few hundred and a few thousand dollars for a tailored abutment. However, in Turkey, the cost for a custom-made abutment is significantly more affordable, with patients typically paying only around £85. Consult a dentist or prosthodontist for an accurate cost estimate according to one's unique requirements.

The benefits of a custom-made abutment include a personalised fit, decreased risk of problems, improved aesthetics, and enhanced longevity. A custom abutment implant is created to blend in with the client's actual teeth along with the surrounding structures, resulting in a more pleasant and realistic-looking dental replacement. They are crucial to the success and pleasure of dental implant patients.

There are potential issues associated with custom-made abutments, which include design or fabrication flaws, even though they are of low risk. Choose a highly qualified and experienced dental practitioner to avoid such dangers and ensure the best outcome. There is a danger of infection, implant failure, or other issues, as with any dental surgical procedure. Such worries, however, pertain more to the implant treatment than the abutment itself.

What are Custom Made Abutments?

Custom-made abutments are specialist dental implantology elements that provide a personalised and perfect connection between a prosthetic tooth and a dental implant fixture, such as a bridge, crown, or denture. The customized abutments are personalised to meet the patient's specific oral architecture, assuring a precise fit and maximum efficiency.

Custom-made abutments are distinguished by their tailored design, which takes into account the specific shapes and alignment of the implant site, resulting in an organised and solid connection. The customised method improves the aesthetic and practical features of the final dental repair, resulting in a more natural and pleasant result.

Custom-made abutments are manufactured using modern processes such as computer-aided design and manufacturing (CAD/CAM) to assure precision and consistency. They are made of high-quality materials, which include titanium, zirconia, or other biocompatible choices, to improve long-term durability and biocompatibility.

The abutments are critical to the long-term success of dental implants because they reduce the likelihood of problems and improve the patient’s experience. Custom abutment is a vital component in current dental implant operations due to its personalised design and accurate fit. People notice increased dental aesthetics, firmness, and delight as a result. The question "What is a custom abutment?" arises in discussions about dental implant procedures, referring to a personalised and precisely crafted component essential for the success and aesthetics of the restoration.

How does Custom Made Abutment differ from Abutment?

A custom-made abutment differs from an abutment in terms of the process it employs, the degree of personalisation it offers, and the level of its accuracy.

An abutment is an intermediary link linking a dental implant fixture and a prosthetic tooth. Abutments are a key component in dental implantology that aims to provide a foundation for the attachment of the final restoration. They promote a solid and aesthetically pleasing attachment between an implant and the prosthetic tooth.

Custom-made abutments differ in their level of customisation and precision from ordinary abutments. Custom-made abutments are individually constructed and customised to the patient's specific oral anatomy, while both types of abutments serve the same basic function. The customisation offers a more precise fit and improved aesthetics.

Standard dental abutments, referred to as stock or prefabricated abutments, are manufactured in large quantities and exist in a few dimensions and shapes. Standard implant abutments provide a more general fit and do not fully meet the patient's dental anatomy. Inferior aesthetics and functioning are experienced as a result.

Custom-made abutments are created using modern processes based on the patient's exact impressions or digital scans. The personalised approach yields a connector that is precisely suited to the patient's implant site, resulting in a more pleasant, natural-looking, and secure dental replacement. Custom-made abutments offer superior alignment and cosmetic results, making them the preferable alternative when precision and individualisation are sought.

How do Custom Made Abutments work?

Custom-made abutments work by establishing a highly personalised and accurate attachment between a dental implant post and a substitute tooth, such as a bridge, denture, or crown. Custom-made abutments are responsible for ensuring the final fit of dental restorations, their stability, and their aesthetics.

The individual's dental structure is carefully examined using digital impressions or physical moulds after the dental implant fixture or post is placed. The detailed records are utilised to develop a custom abutment with innovative technologies such as computer-aided design and manufacturing (CAD/CAM). The CAD or CAM procedures consider the curves, angulation, and distance at the implant site to ensure an excellent fit.

The customised abutment is firmly fastened to the implant fixture once it has been developed. It is the framework to which the artificial tooth is attached. The custom-made abutment's specific fit minimises gaps or misalignments, lowering the occurrence of dangers and boosting the extended viability of the dental prosthesis.

The capacity of custom-made abutments to produce an unobstructed and firm connection reduces the occurrence of complications such as infection, implant failure, and pain. The precision and personalised design of custom-made abutments make for a more satisfying and effective dental implant process, making them a vital element of current implant dentistry.

Who can use Custom Made Abutments?

The individuals who can use custom-made abutments are listed below.

Individuals with Full Arch Implants: Individuals who have lost a whole arch of teeth and choose implant-supported dentures or full-arch prostheses require custom-made abutments. The abutments provide a precise and secure attachment for full-arch restorations, improving posture and ease while regaining the patient's confidence in eating, speaking, and smiling.

Single-tooth implant patients: Custom-made abutments are essential for people who lost a single tooth and want to replace it with a dental implant. The abutments are custom-made to the exact size and orientation required for a single-tooth repair, ensuring a snug fit that perfectly compliments the neighbouring natural teeth.

People with Implant Bridges: Custom-made abutments relieve patients with many tooth extractions, particularly people who require implant-supported bridges. The abutments are designed to effectively hold up the bridge, increasing its aesthetic and functional value. It makes the attachment between the dental implant fixings and the artificial bridge more secure.

Clients with Difficult Anatomical Conditions: Custom-made abutments are useful for people who have unusual or difficult oral anatomical characteristics, such as uneven bone arrangement or unconventional dental gaps. The abutments are designed to accept and adapt to specific physiological obstacles, enabling a secure and personalised connection even in the most difficult of circumstances.

Patients with Special Functional Requirements: Custom-made abutments are created to satisfy certain functional needs, making them ideal for individuals who seek abutments that optimise speech or eating function. The abutments are customised to meet the client's specific functional requirements, boosting convenience and oral efficiency.

Aesthetic Focus clients: People who value appearance benefit from custom-made abutments that are meant to match the colour, shape, and contour of natural teeth, leading to a balanced and visually appealing grin. The abutments guarantee the final repair blends in with the patient's current dentition, improving the cosmetic result of the dental implant operation.

Which Situations Are Custom-made Abutments Used?

The situations where custom-made abutments are used are listed below.

Considerations for Aesthetics: Custom-made abutments are used when aesthetics are a key consideration. The abutments are shaped, coloured, and contoured to match the natural teeth, giving a smooth and visually appealing integration with the patient's smile.

Replacement of Multiple Adjacent Teeth: Custom-made abutments are required when many adjacent teeth are lost and are being replaced with implant-supported bridges. They provide a precise fit for the bridge, assuring stability and performance that ordinary abutments cannot.

Optimal Function and Occlusion: Custom-made abutments are preferred in circumstances where exact occlusion and functional requirements are critical. They are tailored to the patient's unique bite and chewing patterns, assuring maximum comfort and function.

Complete Arch Implant Restorations: Custom-made abutments are used in full arch implant restorations, which replace all of the teeth in an arch with implant-supported dentures or fixed prostheses. The tailored abutments are required to build a sturdy foundation and to maintain optimal occlusion and function throughout the arch.

Complex Anatomy: Patients with unusual or difficult oral anatomy, such as uneven bone structure, angulation differences, or not enough room for standard abutments, need custom-made ones. The abutments are custom-made to fit the individual's anatomy, ensuring a strong connection between the implant and the final restoration.

Adjacent Tooth Preservation: Custom-made abutments are adjusted to reduce interference with the adjoining dentition when a patient has natural teeth close to the implant site. It contributes to the health and integrity of the surrounding teeth.

What is the Role of Custom-Made Abutments in Dental Implants?

The role of custom-made abutments in dental implants is to maintain the functionality, aesthetics, and long-term success of implant-supported restorations. Acting as connectors between the surgically placed implant fixture and the prosthetic component (crown or bridge), these abutments are designed with precision to offer a secure and accurate fit. Its precision reduces the likelihood of complications such as bacterial infiltration or mechanical instability, which improves long-term outcomes, according to numerous studies.

Soft tissue management is one important issue that custom abutments address. Their design takes into account the surrounding soft tissue, ensuring an appropriate emergence profile and contouring. Consideration aids in shaping the gums for a natural and aesthetically pleasing appearance, which is particularly crucial for implants located in visible areas of the mouth.

Optimal aesthetics is another key benefit of custom-made abutments. The individualised shaping and colouring of these abutments facilitate seamless integration with adjacent natural teeth. The personalised approach enhances the appearance of the implant-supported restoration, aligning it harmoniously with the patient's dentition.

Custom abutments improve the prosthetic component's aesthetics, and they add stability and support, whether it is a single crown or a dental bridge. Stability is instrumental in preventing micromovements during functional activities such as chewing, thereby safeguarding the long-term success of the implant.

The patient-specific considerations inherent in custom-made abutments are paramount. Accounting for each patient's unique anatomical features ensures a tailored solution that promotes structural integrity and effective treatment outcomes. Its individualised approach has been associated with a reduced risk of complications, as indicated by studies highlighting lower incidences of issues such as peri-implantitis, which is inflammation around the implant site.

The evidence supporting the role of custom-made abutments in dental implants is multifaceted. Studies that look at precision fit, soft tissue response, aesthetic outcomes, stability, and patient satisfaction show how important these abutments are for personalised and successful implant treatments.

What is the Possibility of Custom-Made Abutments to Affect Implant Treatment Success?

The possibility of custom-made abutments to affect implant treatment success is substantial, with a few key aspects supporting their impact. Custom abutments offer dentists heightened control, particularly in cases involving single implant-supported crowns. Customised abutments, as opposed to stock implant abutments, allow for individualised adjustments, leading to a treatment plan that is more precise and personalised for each patient.

A major benefit of custom-made implant abutments is the improved management of soft tissue, a critical aspect in cases involving crowns and bridges in the anterior region. The customisation facilitates the shaping of an emerging profile that ensures a natural appearance and aligns with aesthetic expectations. Extensive studies underscore the importance of proper soft tissue management for achieving long-term implant success and patient satisfaction.

Aesthetic outcomes are significantly enhanced with custom implant abutments, as they play a pivotal role in optimising the visual appeal of crown and bridge cases. Modifications are easier to accomplish with custom abutments than with stock abutments because they are not premanufactured. It is particularly relevant given the difficulty of achieving an ideal crown preparation with high-speed handpieces when using stock abutments, making custom abutments a preferred choice for patients seeking optimised aesthetic results.

The technological landscape in dental laboratory manufacturing specifically advances in CAD/CAM milling, has had a major impact on the creation of custom implant abutments. The technological strides allow precise milling of abutments to exact specifications, ensuring a seamless fit between the implant platform and the abutment. The precision achieved through these technological advancements was previously challenging, highlighting the positive impact of technology on the success of treatments involving custom abutments.

Efficiency in the delivery process is another contributing factor to the success of custom implant attachments. The precise fit achieved through milling ensures an efficient delivery appointment, while the design of custom abutments allows for easy crown retrievability without disturbing abutment alignment. Its streamlined process positively influences the success of the implant procedure.

The ability of custom-made abutments to provide increased control in treatment planning, improved soft tissue management, enhanced aesthetics, and the integration of technological advancements in dental laboratory manufacturing support the possibility that custom-made abutments affect implant treatment success rates. The factors collectively contribute to positive results in implant treatments where custom abutments are employed, emphasising their role in advancing the quality of care in implant dentistry.

What is the Effect of Custom Made Abutments on Aesthetic Results?

The effect of custom-made abutments on aesthetic results is highly significant, as they represent a personalised and meticulously crafted solution designed to enhance functionality and visual appeal in dental implant restorations.

Using cutting-edge computer-aided design and manufacturing techniques, skilled technicians create custom abutments in dental labs. The process ensures that each abutment is tailored to the patient's dental impressions and specific instructions. The result is a precise fit and seamless integration with the patient's natural teeth. The flawless fit improves the restoration's practicality and its visual attractiveness.

Evidence supporting the aesthetic benefits of custom abutments lies in the meticulous design and craftsmanship involved in their production. The emergence profile of the abutments is customised to match the surrounding dentition and appear natural by taking into account the specific anatomical characteristics of each patient. Custom abutments provide more customisation than standard alternatives, which results in better aesthetic results, according to studies.

Custom abutments have been found to mitigate potential complications associated with bruxism, a common issue where individuals grind or clench their teeth. The personalised fit and design help distribute forces more evenly, reducing the impact of bruxism on the restoration. It enhances the longevity of the implant-supported restoration and contributes to the success of dental implant treatment.

Addressing a common misconception regarding cost, technological advancements and automation in the production of custom abutments have significantly reduced the once-perceived cost-prohibitive nature of these personalised solutions. The performance and aesthetic benefits of custom abutments far outweigh any minimal additional expense. Investing in a custom abutment is considered a prudent choice, as it gives better aesthetic outcomes and saves time and money in the long run by contributing to the success and longevity of dental implant restoration.

How Are Custom-Made Abutments Made?

Custom-made abutments are made in 5 steps that are listed below.

Choosing Abutment Type. Deciding between stock abutments and custom abutments based on specific implant prosthetic requirements is the first step. The crucial decision sets the foundation for the subsequent steps, where customisation and control over various parameters become paramount.

Custom Abutment Fabrication Methods. Exploration of fabrication methods is imperative. It includes considering the UCLA-type abutment and providing control over the emergence profile, height, and angulation. The integration of CAD/CAM technology offers the ability to mill custom abutments from solid titanium, a method that ensures strength and precision in the final product.

Use of Milling Abutments. Employment of "milling abutments" for significant customisation. Using a specialised approach allows for extra material removal and facilitates changes in angles that are challenging to achieve with standard stock abutments. The step underscores the adaptability and flexibility required in crafting custom abutments tailored to unique patient needs.

In-Office Extraoral Protocol. In-office extraoral protocol is a pivotal aspect of the process. The step includes commencing with an implant impression and the meticulous fabrication of a soft-tissue model. The use of a soft-tissue material such as Soft-tissue Moulage around the “crestal” 3 mm of the analogue within the impression ensures accuracy in the subsequent steps. A stone model is poured and the models are articulated on a simple articulator for height adjustment, setting the stage for precise customisation.

Preparation of Milling Abutment. Preparation of the milling abutment involves securing it into the soft-tissue model and tightening the fixation screw to prevent movement during milling. Reduction of the occlusal surface is achieved using a gross-reduction shaping carbide, ensuring clearance for the cusp tips of the custom abutment. A football-shaped carbide for gross reduction is used to smooth out the occlusal surface and tapered carbides for interproximal surface reduction in the back and front teeth. Each step contributes to the meticulous preparation of the custom abutment.

Finalization and Polishing. Finalisation and polishing of the abutment. Marking the abutment for orientation, removing soft-tissue material from the cast, and further reducing circumferential surfaces with gross-reduction shaping carbides contribute to achieving an optimal surface. The polishing step, using titanium finishing carbides, ensures a smooth and refined surface, which is crucial for accurate impression capture.

What are the Materials Used for Custom Made Abutments?

The materials used for custom-made abutments are listed below.

Titanium: Titanium is a widely used material for dental implant abutments due to its excellent biocompatibility, strength, and corrosion resistance. Titanium provides a durable and stable foundation for prosthetic restorations and is preferred for its reliability in long-term use.

Zirconia: Zirconia is a ceramic material known for its aesthetic appeal and tooth-like colour. Zirconia abutments offer a metal-free alternative, providing excellent biocompatibility and a natural appearance. They are chosen for anterior restorations where aesthetics are a primary concern.

Precious Alloy Cast (UCLA Abutment, Telescopic Crowns): Precious alloys, such as gold or other noble metals, are sometimes used in the fabrication of abutments, especially for UCLA abutments and telescopic crowns. The materials provide a high level of precision and strength, although they are less common due to cost considerations.

Resin: Resin-based abutments are occasionally used, particularly in temporary or provisional restorations. Resin abutments are designed to be temporary and work well during the healing process, but they are not as long-lasting as metal options.

PEEK (Polyetherketone): PEEK is a high-performance polymer that is gaining popularity in dentistry. PEEK abutments are lightweight, biocompatible, and have a natural appearance. They are used when a non-metallic solution is desired, and their shock-absorbing properties are beneficial in certain clinical scenarios.

Hybrid Materials: Some abutments are composed of a combination of materials, such as a metal base with a ceramic overlay. The hybrids aim to leverage the strengths of different materials, providing strength and aesthetics.

Composite Materials: Certain composite materials are used in the fabrication of abutments. The materials offer a balance between strength and aesthetics, although they are not as commonly used as other options.

Ceramic Variations: There are variations in ceramic materials that offer specific advantages beyond traditional zirconia. The variations include improvements in translucency, strength, or colour matching.

Metal Alloys: Various metal alloys are used for custom abutments in addition to precious alloys. The choice of alloy impacts factors such as strength, corrosion resistance, and cost.

How to Design Custom-Made Abutments?

To design custom-made abutments, follow the 10 steps below.

Scan and Positioning. Initiate the design process by conducting a thorough scan of the intra-oral or master implant model, utilising specialised scan flags for precise data capture. The flags provide essential information about the fixture's position, enhancing the accuracy of the scanning process.

Software Design. Employ CAD/CAM technology during the software design stage. The software proposes a scenario based on established parameters, taking into account physics and biomechanical factors. Implant technicians actively engage in annotating the desired tooth position and verifying the path of insertion within the software interface.

Abutment Customisation. Utilise software tools to manipulate and customise the proposed abutment. Ensure that the design aligns with established standards for long-term success, incorporating considerations for functional and aesthetic aspects. Sculpting tools within the software facilitate precise adjustments to achieve the desired abutment shape.

Sculpting Tools. Explore sculpting tools available within the CAD/CAM module. Anti-rotational features, such as the "Sculpt" tool's plane cut and attachment options, become instrumental in refining the abutment shape. Technicians carefully employ these tools to create a positive lock and anti-rotation mechanism, enhancing the overall stability of the abutment.

Material Selection. Leverage the material options provided by open-sourced CAD/CAM modules for custom abutments. Choices include zirconia bonded to titanium interphase, full-contour zirconia, complete zirconia, and titanium abutments. The selection depends on factors such as strength, aesthetics, and compatibility with the patient's specific needs.

Zirconia-Titanium Hybrid. A zirconia-titanium hybrid abutment is milled from a zirconia block after the design, manipulation, and selection of the zirconia block. The sintered core is attached to a prefabricated titanium interphase after milling for an ideal fit and aesthetic finish.

All-Zirconia Abutment. The milling process is done without adding a titanium interphase for an all-zirconia abutment. Caution is advised due to potential issues related to inconsistency, implant junction sealing, and the risk of zirconia failures.

Implant Material Selection. Finalise the abutment design, generating a .stl file. Transmit the file to an implant manufacturer or milling centre equipped with advanced CNC machines. The machines execute precise milling, ensuring detailed surfaces and allowing the use of materials such as pure titanium.

Verification and Adjustment. Ensure the milled custom abutment fits and lines up correctly with the implant fixture soon after receiving it. Make any necessary adjustments to ensure optimal integration and alignment.

Finalisation and Delivery. The restoration is finished once the patient is happy with the fit and look of the custom abutment. Deliver the completed custom-made abutment to the dental practitioner for the subsequent implant restoration process.

How Long Does It Take to Complete the Custom-Made Abutments?

Custom-made abutments take 6 to 8 days to complete. The timeline for completing custom-made abutments involves distinct stages, with variations based on the type of impression method employed. Digital impressions, thanks to their improved accuracy and automated workflows, drastically shorten the time it takes to fabricate abutments from six to eight days with physical impressions to three to five days. It is great news for patients and dentists alike.

The adoption of digital impressions enhances the precision of the final product and significantly expedites the design and creation process of dental implant abutments. Laboratories employing a fully automated digital workflow produce a custom abutment within a shorter timeframe, ranging from three to five working days. It represents a notable reduction in the time required for fabrication compared to traditional physical impression methods.

The advantages of digital impressions extend beyond efficiency, contributing to the accelerated production of higher-quality final implant-supported restorations. The streamlined digital workflow allows for a quicker turnaround, enabling patients to receive their custom abutments and associated restorations sooner than is feasible with standard impression techniques.

What is the Durability of Custom Made Abutments?

The durability of custom-made abutments increased due to the utilisation of excellent materials well-known for their durability and wear resistance properties. The enhancement contributes significantly to the extended lifespan of dental implants.

Custom abutments are crafted with precision and attention to detail in dental laboratories. The choice of materials plays a crucial role in determining their durability. Commonly used materials for custom abutments include titanium, zirconia, and other alloys known for their strength and resilience.

Titanium, a frequently employed material for custom abutments, is valued for its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. The properties make titanium an ideal choice for dental implants, contributing to the durability of the abutment.

Zirconia, another prevalent material, is recognised for its robustness and resistance to wear. Custom abutments made from zirconia exhibit high durability, ensuring long-term stability and functionality. Zirconia is known for its aesthetic appeal, providing strength and an attractive appearance.

The durability of custom-made abutments is further supported by advancements in manufacturing techniques, such as CAD/CAM technology. The technology allows precise milling and shaping of abutments, ensuring a perfect fit and optimal load distribution. The use of digital workflows contributes to the quality and durability of the final product.

Circumstances surrounding the durability of custom-made abutments vary based on individual factors. Patient-specific considerations, such as oral hygiene practices, occlusal forces, and health, influence the long-term performance of dental implants. Regular dental check-ups and maintenance are essential to monitor the condition of the abutments and address any potential issues promptly.

The increased durability of custom-made abutments is a result of meticulous craftsmanship and the selection of robust materials. The use of high-quality materials, coupled with advancements in manufacturing technologies, contributes to the longevity and reliability of dental implants, supplying people with a strong and practical solution for replacing their teeth.

How Much Do Custom-Made Abutments Cost?

The cost of custom-made abutments varies, but some dental clinics do not charge patients, such as MyraDental Centre in Turkey. The standard abutment costs £85. Material selections, impression techniques, laboratory fees, and the calibre of the procedure all affect the cost of custom-made abutments. Dentists and patients must carefully consider the long-term benefits and efficiencies provided by custom abutments when evaluating the associated costs.

Several factors and circumstances influence the price of custom-made abutments. The choice of materials plays a role, as higher-grade materials with enhanced properties result in higher charges. The method used for impressions affects costs, with laboratories potentially charging differently based on whether digital impressions or traditional physical impressions are used. Digital workflows are more efficient and precise, reducing manual processing costs.

Individual dental laboratories have varying fee structures and establishments with advanced technology and expertise charge higher fees for their services. Clinicians must consider their operating costs. The use of stock abutments leads to challenges in obtaining a smooth transition between the abutment and crown, potentially requiring more chair time for adjustments.

Custom abutments offer several advantages that justify their costs. They allow for ideal margin placement at or slightly below the crest of the soft tissue, facilitating easier removal of excess cement. It reduces tissue trauma and contributes to efficient chairside procedures. Custom abutments are more expensive than stock abutments, but they last 15–20 years longer due to their durability.

How to Maintain Custom-Made Abutments?

To maintain custom-made abutments, follow the tips listed below.

Rinse the Area Gently: Gently but thoroughly rinse the surrounding area as soon as the healing abutment becomes visible. Use the surgeon's prescribed antibacterial mouthwash to perform the morning rinsing routine.

Initial Tooth Brushing: The day after the surgery, a patient is permitted to brush their teeth. Avoid brushing the gums or the healing abutment at an early stage to prevent any disturbance to the healing process.

Cautious Wiping in Weeks Three and Four: Two or three times daily, gentle wiping of the healing abutment is acceptable in the three to four weeks following surgery. Utilise cotton dipped in the antimicrobial mouthwash for such a purpose.

Continuous Salt Water Rinsing: Repeatedly rinsing with salt water must be part of the recovery regimen. It helps dislodge food particles and plaque without the need for vigorous scrubbing or wiping.

Gradual Introduction of Tooth Brushing: The patient is allowed to start brushing their abutment starting in the fifth week following surgery. Exercise caution and brush gently, avoiding excessive force that harms the gum tissue and the implant.

Dental Flossing: Use dental floss gently by sliding it between the teeth and cleaning around the abutment to maintain oral hygiene.

Thorough Mouth Rinse: Rinse the mouth thoroughly with salt or warm water after the cleaning routine.

Daily Cleaning Routine: Perform these cleaning steps daily to ensure the proper care and cleanliness of the healing area throughout the recovery period.

Keep custom-made abutments in good shape so that bacteria do not build up, infection risks are lower, and the surrounding tissues heal properly for successful implant integration. Consistent care extends the longevity of the dental implant restoration, preserving functionality and aesthetics, minimising complications, and ensuring a smooth recovery process. Adhering to structured maintenance routines is imperative for sustained oral health and the success of dental implant procedures.

What are the Benefits of Custom Made Abutments?

The benefits of custom-made abutments are listed below.

Natural Emergence Profile: Custom abutments are meticulously crafted to replicate the tissue crests of each individual, ensuring a natural emergence profile that seamlessly integrates with the surrounding gum and soft tissue contours.

Customised Crown Margin Depth: The abutments offer the advantage of tailoring the crown margin depth according to the patient's unique dental anatomy, providing a precise and customised fit.

Improved Hygiene and Aesthetics: Crafted with advanced materials such as gold, titanium, or zirconium, custom abutments enhance aesthetics and allow for better oral hygiene maintenance. Their precise fit promotes a cleaner and healthier oral environment.

Alignment with Angled Implants: Custom abutments are designed to align perfectly with angled implants, providing optimal functionality and stability in various clinical situations.

Patient-Specific Fit: Utilising advanced 3D optical scanning, computer software, and precise manufacturing techniques, custom abutments are created with minimal modifications, ensuring a patient-specific fit that conforms precisely to the structure of the original tooth being replaced.

Creation of a Uniquely Tailored Fit: Developed to work harmoniously with the crown of a natural tooth, custom implant abutments are designed to fit around existing gum and soft tissue contours, offering a uniquely tailored fit exclusive to each patient.

Options in Materials: Custom abutments are crafted from various materials, including zirconia, titanium, or anodized in gold hue, providing flexibility in choosing the material that best suits individual preferences and requirements.

Greater Aesthetic Appeal: Especially beneficial in the case of front tooth replacement, custom abutments offer greater aesthetic appeal, even in the presence of gum recession, by precisely replicating the patient's unique dentition.

Perfect Match for the Teeth: Impressions or digital scans of the patient's mouth ensure that custom abutments match the eruption profile of their teeth exactly, resulting in a fixture that perfectly replicates the individual's dentition.

Recommendation for Aesthetic Areas: Stock abutments are quick and cheap, but custom abutments are better for dental implant restorations in areas that need to look good. That is because they meet the patient's standards for function and appearance. Consult with a dentist to determine if a custom dental implant abutment is the right choice.

What are the Risks of Custom Made Abutments?

The risks of custom-made abutments are listed below.

Laboratory Phase Challenges: The downsides of custom-made abutments are mainly linked to the lab phase, introducing challenges related to material selection, fabrication processes, and potential complications.

Cost Considerations: Custom abutments are more expensive than stock abutments, increasing treatment costs. Its financial aspect is a concern for some patients.

Extended Treatment Time: The process of designing and manufacturing custom abutments takes longer compared to using prefabricated stock abutments, potentially extending the overall duration of the implant restoration procedure.

Complexity in Fabrication: Fabricating custom abutments requires precision and attention to detail, posing challenges in achieving the desired fit and alignment. Any errors in the laboratory phase impact the success of the implant restoration.

Material Compatibility Issues: The choice of materials for custom abutments introduces compatibility issues, especially when selecting precious metals to reduce corrosion risk. The interaction between different metals in the abutment and coping is a potential concern.

Risk of Overloading: The customisation of abutments leads to excessive material removal, impacting the strength and load-bearing capacity of the final restoration. Its risk is associated with the need for significant adjustments during the fabrication process.

Potential for Biological Complications: Improper design or fit of custom abutments create spaces where bacteria accumulate, potentially leading to biological complications such as peri-implantitis or soft tissue irritation.

Technical Expertise Requirement: The successful implementation of custom-made abutments demands a high level of technical expertise from the dental practitioner and the laboratory technician. Inexperienced professionals need help achieving optimal outcomes.

Complex Maintenance Requirements: Custom abutments require more intricate maintenance procedures due to their customised nature. Ensuring proper hygiene and regular professional check-ups become crucial to avoid complications.

Material Limitations: Certain limitations exist in the range of materials suitable for custom abutments despite material advancements, impacting the choices available to patients. Material restrictions affect the aesthetic and functional aspects of the restoration.

Complications Related to Two-Metal Interface: The utilisation of castable plastic patterns to fabricate abutments from various precious metals introduces complexities related to the two-metal interface, potentially affecting the longevity and how well the restoration works.

Does Custom-Made Abutments Affect Chewing Function?

Yes, custom-made abutments affect chewing function because they are designed to provide a precise fit and alignment tailored to the patient's unique oral anatomy. They contribute to the stability and functionality of the prosthetic tooth when properly fabricated and integrated into the implant restoration. The customisation ensures that the abutment aligns correctly with the natural teeth, allowing for a more natural chewing motion.

The accuracy of the impression or digital scan, the skill of the laboratory technician, and the materials used in the fabrication process are just a few of the variables that have an impact on chewing function. It has the potential to lead to disruptions in the chewing function in cases where there are errors in design or fit, or if the abutment lacks proper alignment with adjacent teeth.

Dental professionals must ensure that custom-made abutments are meticulously designed, fabricated, and integrated to promote optimal occlusion and chewing mechanics. When done correctly, custom abutments positively contribute to the patient's ability to bite and chew comfortably, mimicking the natural function of the original tooth. Regular follow-ups and adjustments, if necessary, further optimise the chewing function and overall performance of the implant-supported restoration.

Are Custom-Made Abutments Painful?

No, custom-made abutments are not painful. The process of placing custom-made abutments involves a minor surgical procedure where the dentist works specifically with the gums to attach the abutment to the dental implant. The surgical step is comparatively less invasive than the initial implant surgery, which involves placing the metal post into the jawbone. The pain that comes with abutment placement is less severe because it targets soft tissues instead of the bone.

Individuals experience some redness, swelling, and bleeding at the gum line where the abutment is placed during the procedure. Dentists take measures to minimise discomfort, and the pain is usually well-managed with local anaesthesia administered during the surgery. Post-operatively, patients are provided with pain management instructions, including prescribed medications or over-the-counter pain relievers, to alleviate any potential discomfort.

Patients need to follow the dentist's post-operative care guidelines diligently, which include gentle oral hygiene practices and avoiding certain foods or activities during the initial healing period. Regular follow-up appointments allow dentists to monitor the healing progress and address any concerns or discomfort that arise. Custom-made abutments are not a major source of pain, though some patients feel a little sore. It's true when compared to the more complex parts of the dental implant process.

What are the Differences Between Custom Made Abutments and Prefabricated Abutments?

The difference between custom-made abutments and prefabricated abutments lies in the level of customisation. A big part of how well dental implant restorations work is the choice between custom-made and prefabricated abutments. Some clinicians opt for prefabricated abutments to save on the costs and time associated with custom impressions. Prefabricated abutments fall short of providing sufficient support, emergence profile, and contour, leading to aesthetic and functional challenges such as unaesthetic crowns and frequent food impaction.

Custom-made abutments offer a meticulous approach to dental restoration, providing several advantages. Crafted to fit individual tissue crests, these abutments come in gold, titanium, or zirconium, ensuring a precise match for natural teeth. It is particularly beneficial in the aesthetic zone, offering greater appeal even with gum recession. Achieving a perfect fit involves taking impressions or digital scans and considering contour, shape, and eruption profile. The data guides the design process, ensuring a customised fit for each patient. Essential factors such as adequate bone dimensions, soft tissue thickness, and precise implant positioning are considered. Custom abutments allow meticulous control over subgingival contours, margin position, and restoration dimensions.

Prefabricated abutments seem budget-friendly and quicker, but they come with limitations and things to consider. Prefabricated abutments are convenient and save time and money, but they do not always meet the standards for form and function. They lack the support necessary for optimal soft tissue integration and aesthetic outcomes. Prefabricated abutments do not align with adjacent teeth, resulting in complications such as soft tissue inflammation and gingival recession. The risk of complications, including subgingival margin placement and inadequate cement removal, is higher with prefabricated abutments. The complications result in long-term issues such as bone loss and aesthetic failure.

Custom-made abutments are essential for attaining aesthetically pleasing, functional, and hygienic dental implant restorations, even though prefabricated abutments seem to be more convenient and affordable. Dentists, especially restorative dentists, are advised to take full responsibility for abutment layout and placement, ensuring optimal outcomes and patient satisfaction.